Unlike ASTM D6364 “Standard Test Method for Determining Short-Term Compression Behavior of Geosynthetics,” ASTM D1621 “Standard Test Method for Compressive Properties of Rigid Cellular Plastics” is a testing standard designed to measure the compressive properties of rigid cellular plastics (i.e., foam), not geocomposite drainage products. Unfortunately, the geosynthetic community has been saddled with this test method as a carryover from the ASTM D20 plastics committee.

This GSI column is intended to help in understanding the differences in these test methods and will encourage specification of the Geosynthetic ASTM D35 method—ASTM D6364.

Prior to 2006, our industry used ASTM D1621, which provided information regarding the behavior of cellular material under compressive loads (Figure 1a). Deformation data is obtained from a load-deformation curve. The test specimen for this method is either square or circular in cross section with a minimum of 25.8cm2 (4 in.2) and a maximum of 232cm2 (36in.2). The minimum height is 25mm (1in.) and the maximum height no greater than the width or diameter of the specimen. After the specimen is prepared, it is measured for thickness and area, centered between the two compression platens of the constant-rate-of-extension (CRE) machine and loaded at a rate of crosshead displacement of 0.1 in./min for each 1in. of specimen thickness. This is a point of confusion among testing and manufacturers labs, as some use 0.1in./min for stacked samples between 1-2in. and others use 10%/min.

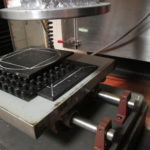

The use of this method was a substitute for the GRI method made specifically for geosynthetic drainage products. One big shortcoming for our industry is that it requires a minimum specimen height (thickness) of 25mm (1in.). To use this method, without calling out a modification, most labs typically stack test specimens with rigid plates in between as shown in Figure 1b, until a minimum height of specimen of 25mm (1in.) is obtained. This gives a complex result but allows a test at a rate of 10%/min, which is a significant factor affecting the compressive strength.

In the early 2000s, ASTM Committee D35 on geosynthetics, working in conjunction with GRI (utilizing GC-4 on the compressive behavior of geosynthetics) generated a method specifically for geosynthetic materials. In 2006, it finally passed the main committee and was adopted under the designation of ASTM D6364, “Standard Test Method for Determining the Short-Term Compression Behavior of Geosynthetics.”

This method always utilizes one layer of the material for testing. As seen in Figure 2a, there is a fixed top plate that is flat, smooth, and completely supported. The movable bottom plate, which is sufficiently thick to preclude any bending during loading, typically sits on linear bearings, ball bearing races, or rollers. In most cases, the specimen is loaded via two parallel plates that are perpendicular to the applied force. There is also a provision in the standard that allows for inclined plates set at a prescribed angle to test the specimen under non-axial load conditions (Figure 2b).

Five specimens are cut from a sample, each being at least 120mm × 120mm (4.7in. × 4.7in.) square. The thickness of each specimen is determined by ASTM D5199 (Standard Test Method for Measuring the Nominal Thickness of Geosynthetics) and then tested at a strain rate of 10% of the nominal thickness per minute or 1mm/minute (0.04 in./min), whichever is greater. The yield is recorded from each specimen and then the average of the five results is obtained. The compressive strength is calculated by dividing this average yield load by the cross-sectional area of the specimen. The results are typically expressed in units of kPa (lb/ft2).

This straightforward approach is applicable to almost all drainage geocomposites and geosynthetics in general. It is theoretically defendable and tests only one layer of material. GSI strongly recommends this method over ASTM D1621 for conformance testing of the relevant materials. It is high time that we stop specifying and testing geosynthetic drainage materials via ASTM D1621. That test is ancient and outdated for our geosynthetic materials, the results of which are not applicable to the properties in question.

TEXTILES.ORG

TEXTILES.ORG